Color EPS | Expandable Polystyrene

Feature of Color EPS Resin

Colored EPS beads retain the lightweight, insulative, and cushioning properties of traditional EPS while adding aesthetic and decorative value due to their vivid colors. This makes colored EPS beads widely used in packaging, decorative materials, toy manufacturing, as well as in advertising and exhibition industries. The extrusion process used to produce colored EPS beads offers designers and manufacturers expanded creative possibilities and applications.

What is Color EPS Bead

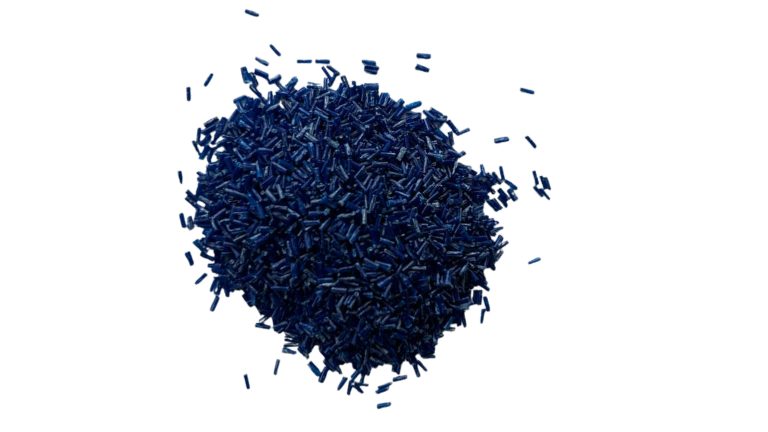

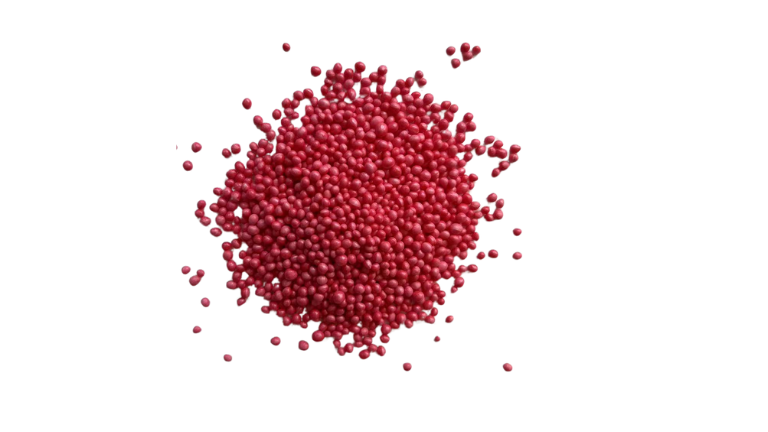

Colored EPS (Expandable Polystyrene) beads are a versatile material that differs from traditional EPS beads, which are typically produced using a suspension process. Instead, colored EPS beads are manufactured through an extrusion process. This involves mixing polystyrene with pigments and other additives, heating and then extruding the mixture through an extruder to form strands, which are subsequently cut into small particles. This production method allows for a more uniform distribution of pigment throughout the polystyrene particles, resulting in EPS beads that are consistently vibrant and colorful.

Application

Uses of Colored EPS Beads

Colored EPS beads are widely used due to their aesthetic appeal and functional properties. They serve as protective cushioning in packaging, add visual appeal to DIY crafts and educational toys, and are integral in manufacturing bicycle helmets and children’s safety seats for shock absorption. Additionally, they are used in construction for lightweight concrete and insulation, in furniture for bean bags and seating, and in the floral industry as fillers for decorative displays.

- Bead size (ball) D 0.8-0.18mm

- Bead size (Cylinder) D 0.5-0.8 mm, L 2.0-2.4mm

- Expansion ratio 20 times